Top China Manufacturers & Suppliers for Polyethylene Injection Molding Solutions

As a premier provider of polyethylene injection molding services, I specialize in delivering customized solutions tailored to your specific needs. With deep knowledge of polyethylene materials, I ensure your products adhere to industry standards and excel in performance across diverse applications. By collaborating closely with specialized injection molding factories, I simplify the sourcing process while offering competitive pricing. My unwavering dedication to quality and customer satisfaction positions me as the ideal partner for your business success.

The Secret to Polyethylene Injection Molding Sets the Industry Standard Service

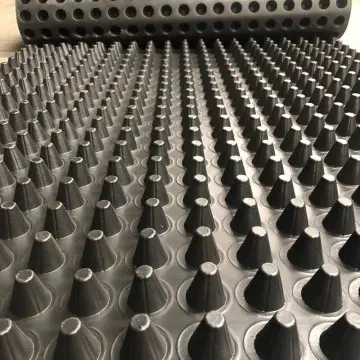

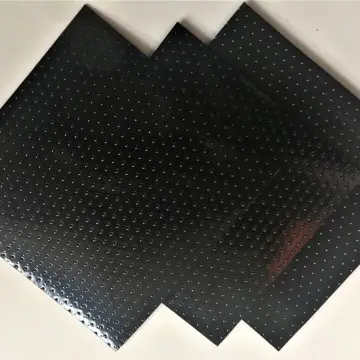

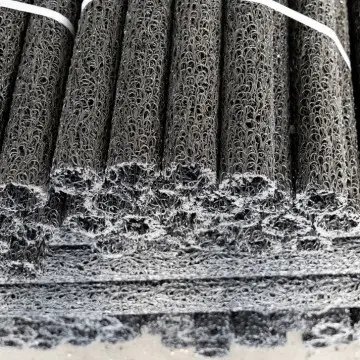

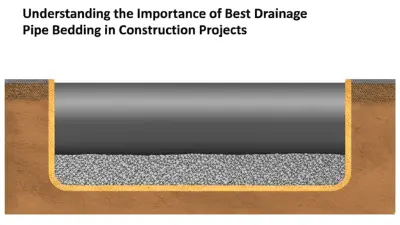

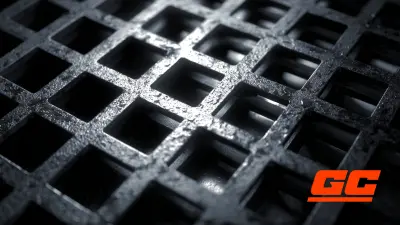

In the ever-evolving world of construction and environmental solutions, polyethylene injection molding has emerged as a critical technology that sets the industry standard for not just quality, but also service. Our company excels in providing an extensive range of high-performance geosynthetic materials, including smooth and rough geomembranes, double color geomembranes, geotextiles, drainage boards, drainage nets, geogrids, geocells, flexible permeable pipes, and plastic blind drains. The meticulous injection molding process we employ ensures that each product meets rigorous industry standards, promising durability and functionality. What truly distinguishes our offerings is our commitment to environmentally friendly practices. As global procurement professionals increasingly seek sustainable solutions, our products are designed to not only meet their functional needs but also to minimize environmental impact. Our advanced polyethylene injection molding capabilities allow us to deliver tailored solutions that meet diverse project requirements while adhering to sustainability goals. By choosing our geosynthetic materials, clients can trust that they are investing in products that drive both performance and ecological responsibility. We understand the challenges you face in sourcing high-quality, sustainable materials. Our dedicated team is here to provide unparalleled service, ensuring that we work collaboratively to meet your specific needs. From initial consultation to product delivery, we prioritize responsiveness and reliability, making us your trusted partner in navigating the complexities of global procurement in the geosynthetic industry. Experience the difference with our polyethylene injection molding technology and take your projects to new heights.

The Secret to Polyethylene Injection Molding Sets the Industry Standard Service

| Parameter | Value | Description |

|---|---|---|

| Material Type | Polyethylene (PE) | Commonly used plastic known for its durability. |

| Melt Flow Index | 0.5 - 2.0 g/10 min | Measure of the flow rate of melted plastic. |

| Injection Pressure | 700 - 1500 psi | Pressure required to inject material into the mold. |

| Cooling Time | 10 - 30 seconds | Time taken for the part to cool in the mold. |

| Cycle Time | 20 - 40 seconds | Time for a complete injection molding cycle. |

| Waste Rate | 1% - 3% | Percentage of material lost during production. |

| Production Volume | 500 - 5000 units/day | Number of parts produced daily. |

Proven Methods To Polyethylene Injection Molding Industry Giant Supplier

P

Patricia Hill

I am very pleased with my purchase. The quality is just as described, and the customer service team was amazing.

28 May 2025

B

Brian Carter

Outstanding quality! Their support staff were very helpful and attentive.

01 July 2025

N

Natalie Brown

This product is fantastic! The after-sale service exceeded my expectations.

06 June 2025

H

Henry Johnson

Top-tier quality! The after-sale support was very attentive and professional.

17 May 2025

V

Victor Hughes

Incredible quality product! The after-sale service was exceptional in every way.

15 May 2025

E

Ethan Lewis

Amazing quality! Their customer service representatives are knowledgeable and very helpful.

15 June 2025