The reasons for adding a protective layer to geosynthetic membranes during construction

Geomembrane is currently widely used in highway pavement maintenance, stadiums, dam protection, isolation of hydraulic structures, coastal tidal flats, reclamation and other projects. Here is a brief introduction to the reasons for adding a protective layer to the product during construction.

Geomembrane needs to be covered with a protective layer during construction and operation, which can provide protection. The reason why it needs a protective layer: The anti-seepage effect of the product depends on the integrity of the plastic film during the construction and operation process. The soil particles in the protective layer shall not be larger than 6 millimeters. If the material does not penetrate the geotextile, it is very easy to puncture the composite material geomembrane. During construction, the surface of the base layer should be leveled with smaller-diameter sand or clay, and then the geomembrane should be laid. To prevent trampling by humans and animals, to avoid damage from plants and animals, and to reduce the effects of light and heat, as it is a high-molecular chemical fiber polymer, it is particularly necessary to avoid direct sunlight. Therefore, the particle size of the product's protective layer should not be too large, otherwise it will puncture the geomembrane.

Geomembrane is a waterproof and barrier material made of high-molecular polymers as the basic raw material. During transportation, geomembrane should not be dragged or pulled hard to avoid being puncched by sharp objects. The specific construction method of geomembrane is as follows:

1. We should extend from the bottom to the higher position. Be careful not to pull too tight. There should be a margin of 1.5 for local sinking and stretching later. Of course, it still depends on the specific usage requirements of our construction site before making a decision.

2. The longitudinal joints of two adjacent pieces should not be on the same horizontal line and should be staggered by more than 1 meter from each other.

3. The longitudinal joints of the geomembrane should be at least 1.5 meters away from the dam foot and the bend foot, and it should be laid on a flat surface.

4. When laying the geomembrane, we adopt the operation method of slope first and then the bottom of the field.

5. When laying the membrane on the slope, the direction of the membrane extension should be basically parallel to the line of the larger slope.

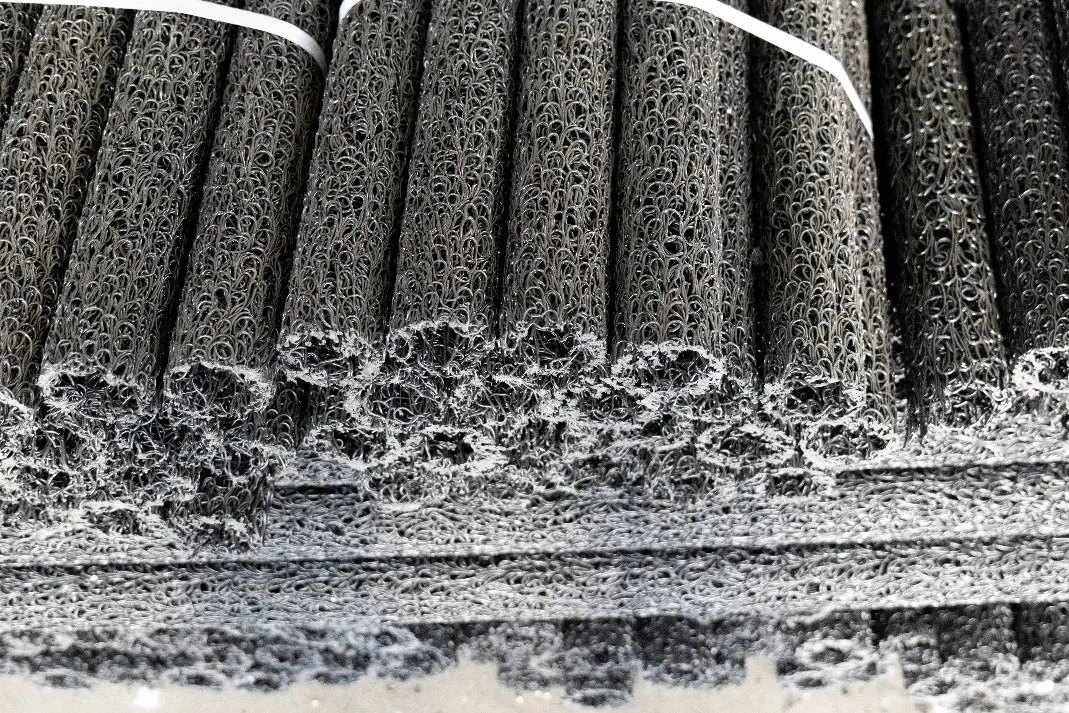

Geotextile, as the protective layer of geomembrane, protects the anti-seepage layer from damage. The correct usage method can achieve good usage effects and avoid unnecessary troubles.