The application of geomembrane in anti-seepage of reservoir projects

With the application effectiveness of geomembrane in water conservancy and emergency rescue projects, this low-cost and well-applicable anti-seepage material has gained the attention of technicians in many engineering projects, and its application scope and methods are also gradually expanding. Meanwhile, with the refinement and more standardized requirements for construction techniques from various perspectives, the wide applicability and scalability of geomembranes are gradually being brought into play. In water storage pool projects, this material also has a relatively ideal anti-seepage effect and reliable anti-seepage construction technology.

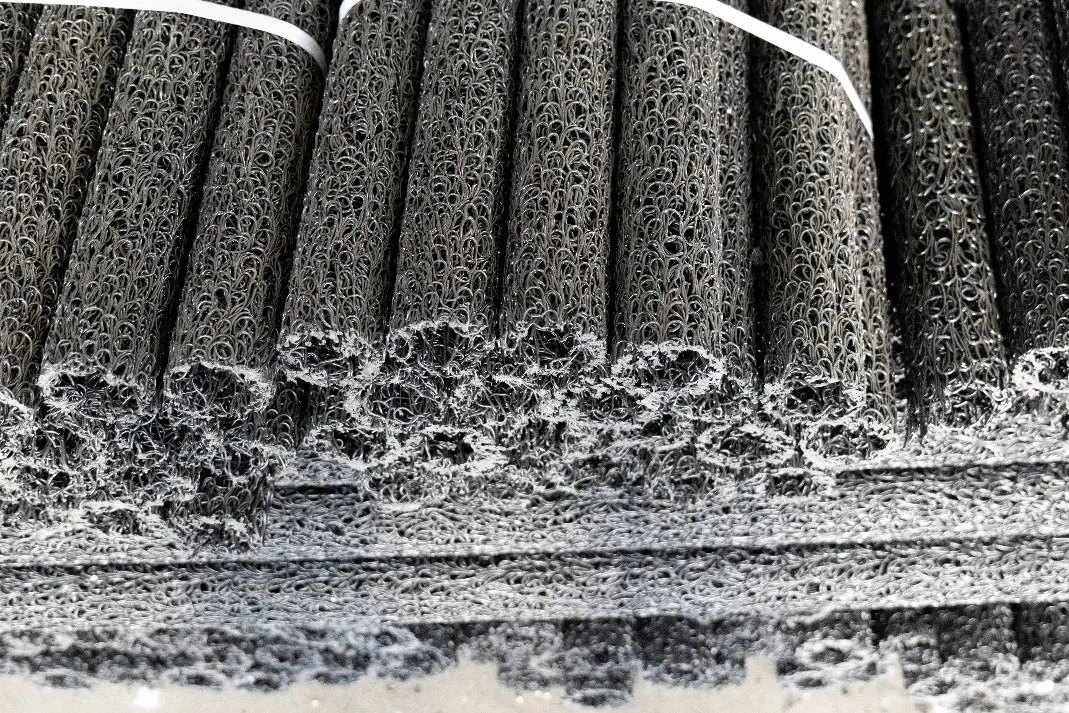

In the anti-seepage application of reservoir projects, composite type geomembranes are often used. According to the classification of anti-seepage membrane materials, they can be further divided into types such as PE and PVC. By combining the composite effect of geotextiles, multiple structures of composite types can also be formed. This not only enhances the strength and applicability but also ensures the feasibility of the engineering anti-seepage technology and the reliability of the overall design.

In the construction of geomembrane anti-seepage for water storage tanks, the first step is to strictly follow the previously designated procedures and norms for construction operations, and strictly control the anti-seepage technical standards of each link. The multiple process links such as laying, welding and inspection should be strictly recorded. During the laying process, it should not be too tight. Pay attention to leaving an appropriate degree of looseness to maintain a proper balance of tension and relaxation, so as to facilitate the subsequent welding operation. After the above steps are completed, timely inspections should be carried out, using the industry's inspection methods. Any leakage points found should be repaired promptly to ensure that the anti-seepage effect and technical indicators meet the standards.

When selecting materials for geomembranes, it is necessary to choose based on the on-site temperature difference and the characteristics of the soil environment. For areas with harsh environments, materials of better specifications should be selected to ensure that the strength can better adapt to erosion in harsh environments, as well as to guarantee the service life and better project quality. As the foundation needs to be prepared before the construction to provide good fit and support, fine-grained soil or sand should be used as much as possible, and surface debris should be cleared to prevent unnecessary damage during the anti-seepage construction of the reservoir.

For the extensive application of geomembranes in reservoir projects, corresponding anti-seepage technologies will also be updated and innovated to achieve better, higher and more stable goals. However, only by strictly controlling and implementing each process link of geomembrane anti-seepage construction, and strictly carrying out supervision and inspection, can the overall anti-seepage construction quality of the project be guaranteed.