Premium LDPE Polymers from Trusted Factories and Reliable Suppliers for Your Needs

At our company, we focus on providing top-quality LDPE polymers that serve a wide range of industrial applications. We recognize the crucial role that dependable materials play in your projects. Our LDPE polymers are celebrated for their exceptional flexibility, durability, and chemical resistance, making them suitable for various uses. Choosing a reliable manufacturer is essential for maintaining material quality—and we pride ourselves on our established reputation for excellence. Whether you require sustainable packaging solutions or cutting-edge materials, our dedicated team is prepared to assist you. Partner with us to access LDPE polymers that meet the highest industry standards, ensuring your business's continued success. Reach out to discuss how we can fulfill your specific requirements.Methods To Choose Ldpe Polymers Manufacturer Supplier

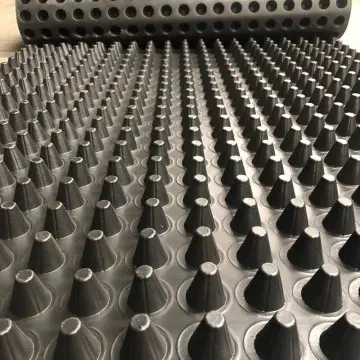

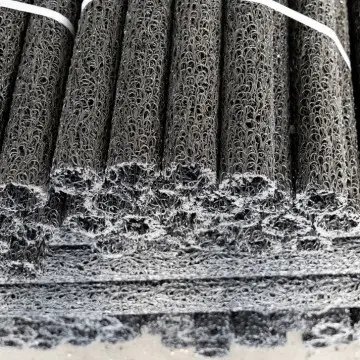

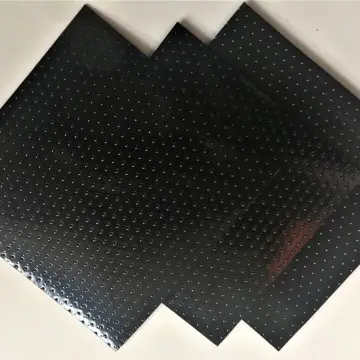

When selecting an LDPE polymer manufacturer and supplier, global buyers should prioritize a few critical aspects to ensure they partner with a reputable and reliable source. First and foremost, assess the manufacturer's expertise in producing quality geomembranes and related geosynthetic materials. Look for suppliers that specialize in a diverse range of products, such as smooth and rough geomembranes, double color geomembranes, and various drainage solutions like geotextiles and drainage boards. A company like ours, which offers a broad array of environmental friendly geosynthetics, can provide valuable insight and innovative solutions tailored to your specific project needs. Another essential factor is the manufacturer's commitment to sustainability and environmental policies. In today's market, it's vital to choose partners who prioritize eco-friendly practices in their production processes. Our firm focuses on creating environmentally conscious materials that not only meet industry standards but also contribute to sustainable project outcomes. By opting for a manufacturer dedicated to such principles, you can seamlessly align your procurement strategy with global sustainability goals. Lastly, consider the supplier's ability to provide consistent quality and reliable delivery. Prospective buyers should request samples and review certifications to ensure that the products meet requisite industry specifications. Establishing open lines of communication regarding product availability, lead times, and after-sales support can significantly enhance your purchasing experience. By meticulously evaluating these factors, you can confidently partner with a dependable LDPE polymer manufacturer that aligns with your project's objectives and contributes to the overall success of your ventures.

Methods To Choose Ldpe Polymers Manufacturer Supplier

| Criteria | Details | Importance Level |

|---|---|---|

| Experience in LDPE Production | Years of experience in manufacturing LDPE polymers. | High |

| Certification and Compliance | ISO certifications, as well as compliance with safety and environmental regulations. | Very High |

| Quality Control Processes | Details on the manufacturer's quality assurance and testing methods. | High |

| Production Capacity | Ability to meet large orders and rush requests. | Medium |

| Customer Support | Availability of support and responsiveness to inquiries. | High |

| Pricing Structure | Competitiveness and transparency in pricing. | Medium |

| Delivery Times | Average time taken for delivery post-order confirmation. | High |

| Reputation and Reviews | Customer feedback and industry reputation. | Very High |

Methods To Choose Ldpe Polymers Manufacturer Factory

T

Thomas Scott

Excellent craftsmanship and quality throughout the product. Their customer service was equally exceptional!

20 May 2025

N

Nicole Lewis

Very happy with my purchase! The quality is excellent, and the after-sale service was proactive!

09 May 2025

J

Joseph Taylor

What a fantastic quality product! Their customer service team was professional and extremely helpful.

22 June 2025

K

Katie Hall

Excellent purchase! The quality was as promised, and the customer service was fantastic.

01 June 2025

M

Mark Scott

Great experience! The quality of the product was exceptional and the service team was very knowledgeable.

20 June 2025

M

Matthew Wilson

This product is exactly what I was looking for. The quality is outstanding, and the support was top-notch.

26 May 2025