High-Quality HDPE Geomembrane Welding Machines from Leading Chinese Manufacturers

When it comes to HDPE geomembrane welding machines, we understand that every project requires unique solutions. Our factory is committed to quality and innovation, offering a variety of customized options tailored to meet the diverse demands of various industries. Designed with precision and built for durability, our machines ensure optimal performance for contractors, suppliers, and manufacturers alike. Partnering with Taian Changhong Engineering Materials Co., Ltd., we leverage our engineering expertise and dedication to quality to stand out in the market. Our aim is to equip you with tools that boost productivity and enhance operational efficiency. Selecting our welding machines means engaging in a partnership focused on your success. Let us help you find the ideal HDPE geomembrane welding machine that aligns with your specifications and supports your business growth.Tips & Tricks for Hdpe Geomembrane Welding Machine Industry Leaders Products

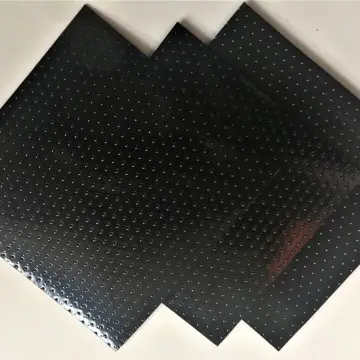

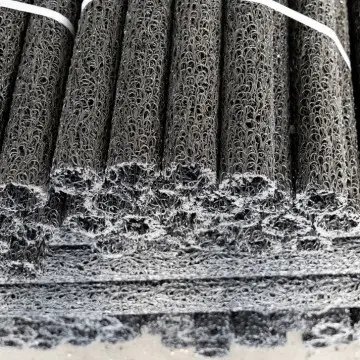

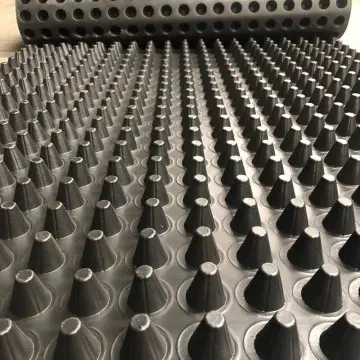

In the rapidly evolving landscape of the geomembrane industry, staying at the forefront of technology and innovation is essential for leaders. One key area that significantly impacts productivity and quality is the efficient welding of HDPE geomembranes. By employing advanced welding techniques and high-quality machinery, companies can ensure superior performance and durability of their geosynthetic products. Investing in state-of-the-art welding machines not only streamlines production but also enhances the integrity of the final product, reducing the risk of leaks and environmental contamination. Furthermore, understanding the specific requirements of various applications, from landfill liners to wastewater treatment, is crucial for optimizing geomembrane performance. Industry leaders should prioritize training for their operators to master welding techniques, as well as regular maintenance of their welding equipment to maintain peak operational efficiency. This commitment to quality is particularly vital when producing a diverse range of products, including smooth and rough geomembranes, geotextiles, drainage boards, and geogrids, which all require precise welding techniques to meet stringent environmental standards. By focusing on these tips and tricks in welding processes, geomembrane manufacturers can not only improve their product offerings but also foster lasting relationships with global partners. As demand for environmentally friendly geosynthetic materials continues to rise, organizations that leverage advanced welding technology will position themselves as leaders in the industry, capable of meeting the demanding needs of procurement professionals across the globe.

Tips & Tricks for Hdpe Geomembrane Welding Machine Industry Leaders Products

| Dimension | Specification | Material Type | Welding Technique | Performance Rating |

|---|---|---|---|---|

| Thickness | 1.5 mm | HDPE | Hot Wedge | Excellent |

| Width | 4 m | LLDPE | Extrusion | Good |

| Length | 100 m | PVC | Hot Air | Very Good |

| Temperature Range | -30°C to 60°C | PP | Ultrasonic | Excellent |

Best Chinese Hdpe Geomembrane Welding Machine Factory Factory-Direct Excellence

E

Emily Rodriguez

The quality is superb! I also found the after-sale support to be very attentive and helpful.

06 July 2025

P

Peter Johnson

The detailing in this product is impressive! The after-sale support was prompt and professional.

11 May 2025

E

Emily Hughes

Truly impressed with the quality! The after-sale support was also very quick and efficient.

17 June 2025

L

Laura Jackson

I absolutely love this product! The quality is fantastic and their support team showed great expertise.

10 May 2025

A

Austin Green

I love this product! The quality is superb, and the customer service team was exceptionally attentive.

25 June 2025

R

Ruth Scott

The quality is beyond what I imagined! The service staff were very attentive and helpful.

26 June 2025