Custom Geotextile Membrane 4.5m x 100m Roll from Trusted Suppliers and Factories

Our Geotextile Membrane 4.5 M x 100 m Roll is engineered for superior durability and efficiency, making it a top choice for various applications such as erosion control and drainage systems. As a trusted manufacturer and wholesaler, Taian Changhong Engineering Materials Co., Ltd. is dedicated to delivering excellence in every roll. We cater to buyer needs with competitive pricing, ensuring that our high-quality geotextile membrane provides effective soil stabilization and moisture management. Partnering with us means accessing reliable products that enhance project outcomes and contribute to lasting customer satisfaction. Choose us for your wholesale requirements and benefit from our commitment to quality.

Key Methods For Geotextile Membrane 4.5 Mx 100m Roll Ahead of the Curve Dominates

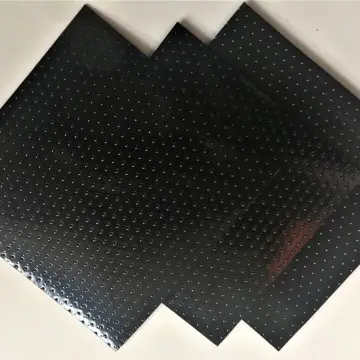

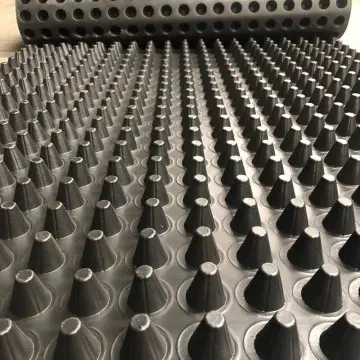

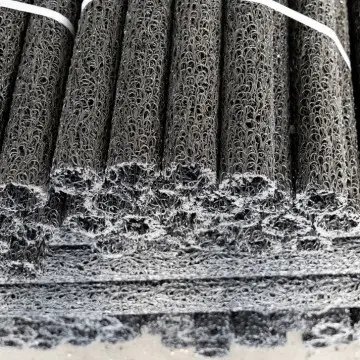

In the ever-evolving landscape of geosynthetic materials, our company stands out with its high-quality offerings, particularly the Geotextile Membrane in the handy 4.5 M x 100 m roll size. This remarkable product not only meets the rigorous demands of contemporary construction and environmental projects but also positions itself at the forefront of innovation and sustainability. The smooth and rough geomembranes, engineered to deliver exceptional durability and versatility, have become essential components in a variety of applications including containment systems, landfills, and environmental protection measures. The use of geotextile membranes plays a critical role in enhancing soil stability and preventing erosion. Our products, coupled with advanced geogrid and geocell technologies, provide superior reinforcement and drainage solutions. These innovations not only ensure structural integrity but also promote eco-friendly practices by minimizing waste and optimizing resource usage. As global procurement professionals seek reliable materials that deliver both performance and sustainability, our geosynthetics are designed to exceed expectations while adhering to industry standards. By choosing our high-performance geotextile membranes, you position your projects ahead of the curve. With a commitment to quality and sustainability, we are dedicated to providing solutions that empower businesses to meet their goals effectively. Explore the advantages of our geosynthetic materials and discover how they can become integral to your next project, ensuring long-lasting success and environmental responsibility.

Key Methods For Geotextile Membrane 4.5 Mx 100m Roll Ahead of the Curve Dominates

| Method | Description | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Heat Bonding | Uses heat to melt edges together | Landfills, erosion control | Strong seams, weather resistant | Requires specific equipment |

| Sewing | Stitches polyester or polypropylene threads | Drainage systems, roads | Flexible, easy to repair | Can be less durable in wet conditions |

| Adhesive Bonding | Uses adhesive to bond materials | Wetland restoration, agriculture | Quick application, minimal equipment | Adhesive can degrade over time |

| Mechanical Fastening | Uses screws or stakes to secure | Construction sites, slopes | High strength, reusable | Installation can be labor-intensive |

| Ultrasonic Welding | Uses high-frequency sound waves | Geotechnical applications, ponds | Strong, continuous seams | Requires specialized equipment |

7 Key Tips To Geotextile Membrane 4.5 Mx 100m Roll Leads the Global Market Supplier

A

Angela Thompson

This item exceeded my expectations. The support team was very helpful and approached my issues professionally.

19 June 2025

E

Edward Ramirez

Top quality product! Their after-sale service was swift and the staff were very knowledgeable.

11 May 2025

R

Robert Johnson

Superb quality! The support staff were friendly and very proficient in addressing my concerns.

22 May 2025

J

Jeremy Smith

The quality here is unmatched! I appreciate the excellent service from their customer support team.

16 May 2025

N

Natalie Brown

This product is fantastic! The after-sale service exceeded my expectations.

06 June 2025

K

Katherine Wilson

Outstanding product! Customer service representatives were quick and very helpful.

18 June 2025