Top HDPE Manufacturers in China: Trusted Suppliers & Quality Factories

As a premier provider of HDPE products, we are committed to delivering unparalleled quality and innovation for a variety of applications. Our comprehensive selection of HDPE types is designed to meet the specific needs of wholesalers and manufacturers alike, making us a trusted partner in the industry. With a focus on exceeding international quality standards, Taian Changhong Engineering Materials Co., Ltd. offers exceptional service and competitive pricing. Our dedicated team is well-versed in the unique demands of B2B customers, ensuring tailored solutions that support your business objectives. Whether seeking bulk orders or specialized HDPE types, we possess the expertise and resources to fulfill your requirements. Partner with us to elevate your business in the HDPE market.Key Methods For China Top Hdpe Types Manufacturer From Concept to Delivery Factory

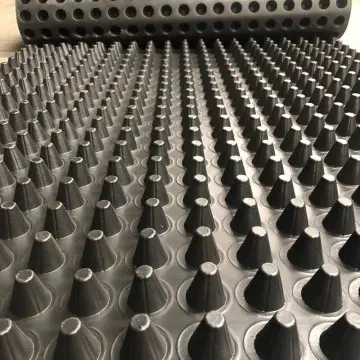

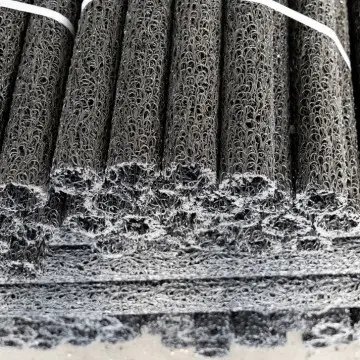

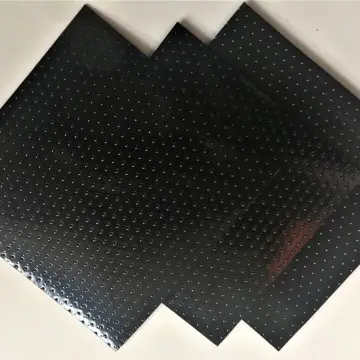

When sourcing high-density polyethylene (HDPE) materials, particularly for geosynthetic applications, understanding the manufacturing processes is crucial. Leading manufacturers in China have honed their capabilities to offer a variety of products effectively, from concept to delivery. They specialize in the production of smooth and rough geomembranes, double color geomembranes, geotextiles, drainage boards, and more, catering to diverse environmental needs. The process begins with meticulous research and development, ensuring that each product meets international standards and customer specifications. The manufacturing journey includes advanced techniques that ensure durability and functionality of products like geogrids, geocells, and flexible permeable pipes. Quality control measures are integrated at every stage of production, ensuring that each item delivered can withstand demanding conditions. Additionally, these manufacturers often employ environmentally friendly practices, which not only support sustainability but also enhance the appeal of their products in global markets. Once the manufacturing and quality checks are complete, the logistics involved in delivering these materials worldwide are seamless. Experienced teams ensure that the products reach their destinations on time and in perfect condition, facilitating a hassle-free supply chain experience for international customers. With expertise in crafting high-quality geosynthetic materials, manufacturers are equipped to meet the growing demands for eco-friendly and efficient solutions in various industries.

Key Methods For China Top Hdpe Types Manufacturer From Concept to Delivery Factory

| Method | Description | Advantages | Applications | Delivery Time |

|---|---|---|---|---|

| Injection Molding | A manufacturing process for producing parts by injecting material into a mold. | High precision, complex shapes, and efficient production. | Bottles, containers, automotive parts. | 2-4 weeks |

| Blow Molding | A process used to create hollow plastic parts by inflating a heated plastic tube. | Excellent for creating large and hollow structures. | Bottles, tanks, and large containers. | 3-5 weeks |

| Rotational Molding | A process that produces large, hollow parts by rotating a mold filled with plastic. | Can create large and thick-walled items. | Tanks, playground equipment, and storage containers. | 4-6 weeks |

| Extrusion | A process for creating objects with a fixed cross-sectional profile by forcing material through a die. | Continuous production and versatile shapes. | Pipes, sheets, and films. | 2-3 weeks |

| Thermoforming | A process that uses heat to soften a plastic sheet, which is then molded into a desired shape. | Lowest cost for large parts; minimal waste. | Packaging, trays, and lids. | 1-3 weeks |

Exploring China Top Hdpe Types Manufacturer Application Where Service Meets Innovation

R

Rachel Adams

This item is exactly what I needed! The post-purchase support was outstanding, and the service staff were very knowledgeable.

04 June 2025

D

Daniel Lewis

This purchase was worth every penny! Exceptional quality and the service team was very professional.

03 June 2025

S

Samuel Carter

Impressive quality! The service staff were knowledgeable and assisted me promptly with my questions.

16 June 2025

E

Emily Hughes

Truly impressed with the quality! The after-sale support was also very quick and efficient.

17 June 2025

S

Susan White

The quality exceeded my expectations! I am also impressed with the professionalism of their support staff.

22 June 2025

P

Paul Lewis

Very impressed with the quality! The service staff were knowledgeable, making my experience seamless.

19 May 2025