Top 5 HDPE Manufacturers in China: Quality Products from Leading Factories

As a B2B purchaser, I prioritize finding reliable suppliers who deliver high-quality products. One standout company in this realm is Taian Changhong Engineering Materials Co., Ltd., a leading manufacturer of HDPE materials in China. Their impressive range of products adheres to stringent quality standards, making them a trusted choice in the industry. They serve various sectors, ensuring that I can always secure the right solutions for my requirements. With a strong focus on quality and customer satisfaction, Taian Changhong has earned a reputable standing. Partnering with suppliers of this caliber allows me to provide top-tier results to my clients and enhances the overall reliability of my procurement process. If you seek dependable HDPE material suppliers, consider making this factory a key part of your supply chain.How To Identify China Leading 5 Hdpe Factories Guarantees Peak Performance Is The Best

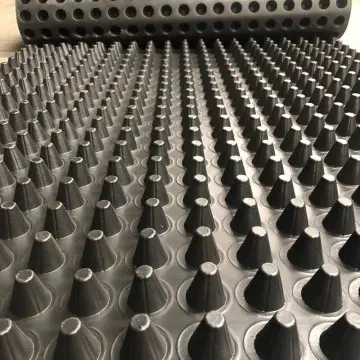

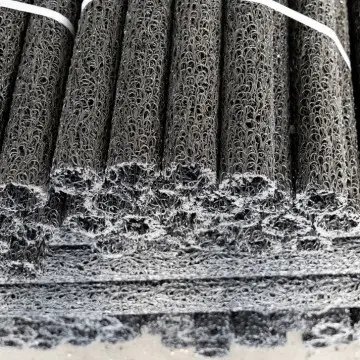

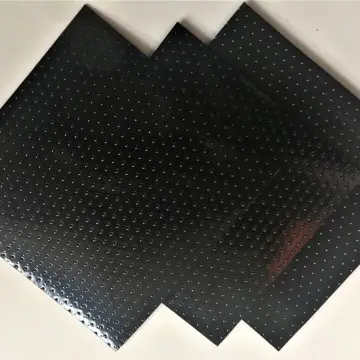

Identifying leading HDPE factories in China is essential for global buyers seeking reliable partners that ensure peak performance in their projects. The first criterion to consider is the factory’s specialization in advanced geosynthetic materials. Factories that produce a variety of products, such as smooth and rough geomembranes, geotextiles, drainage boards, and geogrids, tend to have better expertise and quality control processes. A comprehensive product range suggests that the factory has the necessary technology and experience to deliver high-performance materials that meet diverse application needs. Next, evaluating the factory’s certifications and compliance with international standards is crucial. Trusted Chinese manufacturers often possess ISO certifications and adhere to environmental regulations, ensuring that their products not only meet quality expectations but also promote sustainability. Potential buyers should also consider the factory’s experience in the industry. Established manufacturers with a robust track record are likely to offer better reliability, timely deliveries, and responsive customer service, which are critical for successful project execution. Lastly, engaging with previous clients or exploring online reviews can provide valuable insights into a factory’s reputation and performance. Strong partnerships are built on consistent quality and support, so only those factories that have garnered positive feedback from buyers should be prioritized. By meticulously assessing these factors, global purchasers can identify the leading HDPE factories in China that guarantee exceptional performance and enhance the success of their projects.

How To Identify China Leading 5 Hdpe Factories Guarantees Peak Performance Is The Best

| Factory Location | Production Capacity (tons/year) | Product Types | Certifications | Sustainability Practices |

|---|---|---|---|---|

| Shanghai | 100,000 | HDPE Sheets, Pipes | ISO 9001, CE | Recycling Initiatives, Energy Efficiency |

| Guangzhou | 80,000 | HDPE Bottles, Containers | FDA, ISO 14001 | Water Conservation, Waste Reduction |

| Shenzhen | 120,000 | HDPE Films, Flexible Packaging | BRC, REACH | Biodegradable Options, Reduced Emissions |

| Tianjin | 90,000 | HDPE Pipes, Fittings | ISO 9001, OHSAS 18001 | Closed-Loop Recycling, Solar Energy |

| Beijing | 110,000 | HDPE Blocks, Films | ISO 14001, CCS | Carbon Offset Programs, Green Certifications |

Today's Choice of China Leading 5 Hdpe Factories Is The Best Service Backed by Expertise

D

Daniel Lewis

This purchase was worth every penny! Exceptional quality and the service team was very professional.

03 June 2025

N

Nicole Lewis

Very happy with my purchase! The quality is excellent, and the after-sale service was proactive!

09 May 2025

D

Diana Walker

What a great purchase! The quality is exceptional and the support staff were very polite and knowledgeable.

03 July 2025

R

Robert Anderson

Very pleased with my purchase! The quality is exceptional and the team was very helpful.

23 June 2025

A

Annie Martinez

Standing ovation for the quality! The service team displayed great professionalism.

17 May 2025

V

Victor Hughes

Incredible quality product! The after-sale service was exceptional in every way.

15 May 2025