Effective water management is essential for sustainable development and environmental protection, particularly in urban areas where the impact of stormwater runoff can lead to serious flooding and infrastructure damage. According to a report by the U.S. Environmental Protection Agency (EPA), approximately 46% of America's rivers and streams are currently polluted, largely due to inadequate drainage systems. This highlights the critical need for selecting the right drainage materials to enhance water management practices.

The use of high-quality drainage materials not only helps in the efficient removal of excess water but also plays a vital role in mitigating erosion, maintaining soil structure, and ensuring the health of surrounding ecosystems. Studies suggest that investing in proper drainage solutions can reduce the potential for water-related disasters by up to 30%. By understanding the properties and applications of various drainage materials, professionals can implement more sustainable designs that effectively address both current and future water management challenges.

The following exploration of the top 10 essential drainage materials will provide valuable insights for engineers, architects, and environmental planners aiming to optimize their water management strategies. By utilizing these materials, communities can enhance resilience against flooding while promoting ecological balance and sustainable land use.

Effective water management is crucial for both urban and rural areas, as it minimizes the risk of flooding and ensures the sustainable use of water resources. Drainage materials play a vital role in this process, helping to direct excess water away from vulnerable areas, protect infrastructure, and maintain soil health. Understanding the importance of various drainage materials can lead to better decision-making in projects involving landscape design, construction, and agricultural practices.

When selecting drainage materials, it is essential to consider their permeability and durability. Materials like aggregate stones, geotextiles, and perforated pipes are commonly used for their effectiveness in water flow management. Integrating these materials wisely not only prevents water accumulation but also enhances the ground's ability to absorb rainwater, reducing runoff and erosion.

Tips: Always assess the specific drainage needs of the area before choosing materials. For example, in heavy rain zones, opt for materials that provide high permeability, while in areas with less rainfall, a different combination of drainage materials may suffice. Additionally, regularly maintain drainage systems to ensure they function optimally and prevent blockages that could lead to water pooling and other issues.

When considering effective water management, selecting the right drainage materials is crucial. The key characteristics of effective drainage materials include high permeability, durability, and resistance to clogging. High permeability ensures that water can flow through the material efficiently, preventing overflow and standing water. Durability is essential to withstand varying weather conditions and the weight of overlying materials, while resistance to clogging ensures that the drainage system remains functional over time.

Tips for choosing the right drainage materials include assessing the specific water management needs of your project. For instance, if you're dealing with a high volume of rainfall, opting for materials with enhanced filtration properties can significantly improve performance. Additionally, considering the local soil type and hydrology can help in selecting materials that complement the natural drainage patterns of the area.

Another important aspect is the installation process. Proper installation can maximize the effectiveness of drainage materials, ensuring that they perform as intended. It's essential to follow best practices, such as grading and layering, to facilitate optimal water flow. Regular maintenance checks can also prolong the lifespan of your drainage system, allowing for timely interventions before problems escalate.

Effective drainage systems are crucial for managing excess water and preventing flooding, particularly in urban environments. The selection of materials for these systems can significantly impact their efficiency and longevity. According to a report from the American Society of Civil Engineers (ASCE), outdated drainage infrastructure results in billions of dollars in damages each year, emphasizing the importance of using the right materials for sustainable water management.

One of the key materials essential for drainage systems is aggregate, which provides the necessary void spaces for water movement. Studies show that properly graded gravel can enhance water infiltration rates, reducing surface runoff by up to 30%. Similarly, advanced geosynthetic materials like permeable membranes are becoming increasingly popular, as they allow for effective filtration and drainage while supporting soil stability. The 2022 Infrastructure Report Card highlighted that using innovative materials can extend the lifespan of drainage systems by as much as 40%, resulting in long-term cost savings for municipalities.

Additionally, the use of drain tiles and perforated pipes has been proven effective in subsurface drainage, allowing for better management of groundwater levels. Research indicates that the incorporation of these materials can lead to a reduction in soil erosion and improved agricultural productivity, demonstrating their importance beyond urban applications. As water management challenges continue to grow, investing in essential drainage materials becomes imperative for creating resilient infrastructures.

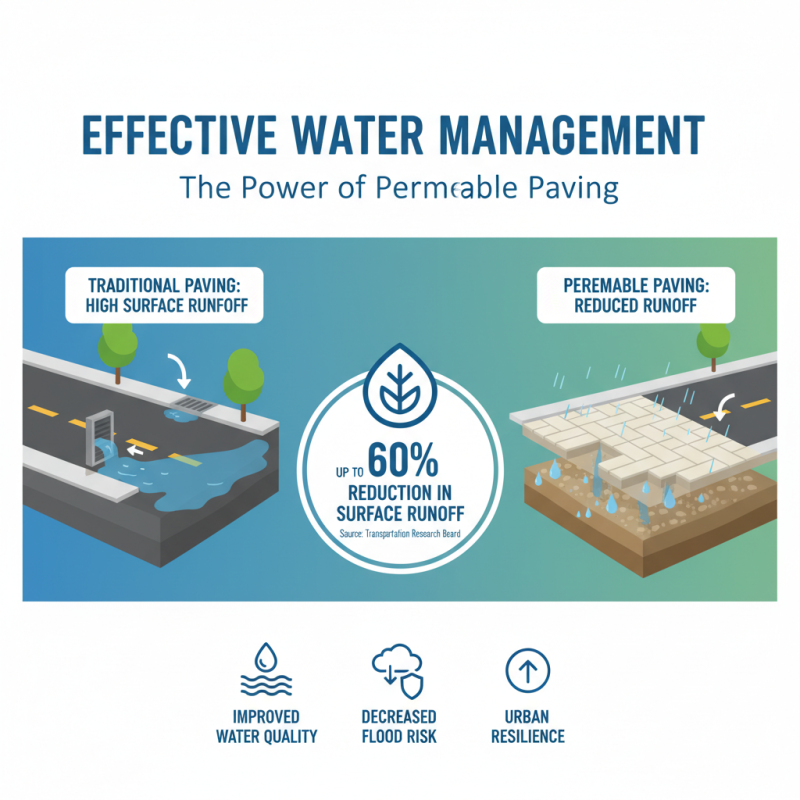

Effective water management relies heavily on the selection and application of the right drainage materials. The use of permeable paving solutions, for instance, can significantly reduce surface runoff by allowing water to infiltrate through the ground. According to the Transportation Research Board, utilizing permeable materials can decrease surface runoff by up to 60%, thereby contributing to improved water quality and the reduction of flooding risks in urban environments.

Incorporating proper application techniques is critical for maximizing the performance of these drainage materials. For instance, ensuring correct grading and slope can enhance the drainage efficiency, allowing for the swift removal of excess water. Additionally, maintaining adequate maintenance protocols, such as regular inspections and sediment removal, is necessary to uphold the functionality of the drainage systems. Data from the American Society of Civil Engineers indicate that routine maintenance can extend the lifespan of drainage systems by as much as 25%, ensuring they effectively manage water during heavy rainfall events. Thus, understanding both the materials and techniques is essential for implementing a successful water management strategy.

When considering drainage materials for effective water management, maintenance is a critical aspect that often gets overlooked. According to the American Society of Civil Engineers, a staggering 40% of water infrastructure failures can be attributed to inadequate maintenance practices. Regular inspections and proper upkeep of drainage systems not only enhance their longevity but also significantly improve their performance in managing water flow.

One of the key considerations in maintaining drainage materials is to ensure that they remain free from blockages and debris. For instance, a report by the U.S. Environmental Protection Agency indicates that clogged drains can reduce system efficiency by up to 50%. Implementing a routine cleaning schedule, particularly after heavy rainfall, can prevent sediment buildup and keep water channels flowing smoothly. Additionally, the materials used often experience wear and tear; therefore, periodic assessments should be conducted to identify signs of erosion, corrosion, or other forms of damage.

Moreover, the choice of drainage materials can affect maintenance frequency and complexity. Studies have shown that high-density polyethylene (HDPE) pipes, for instance, can last up to 100 years with minimal maintenance, compared to traditional materials that may require replacements every 30-50 years. Selecting durable materials from the outset can significantly decrease long-term maintenance costs and improve overall water management effectiveness, making it imperative for professionals in the construction and civil engineering fields to prioritize material selection alongside maintenance strategies.