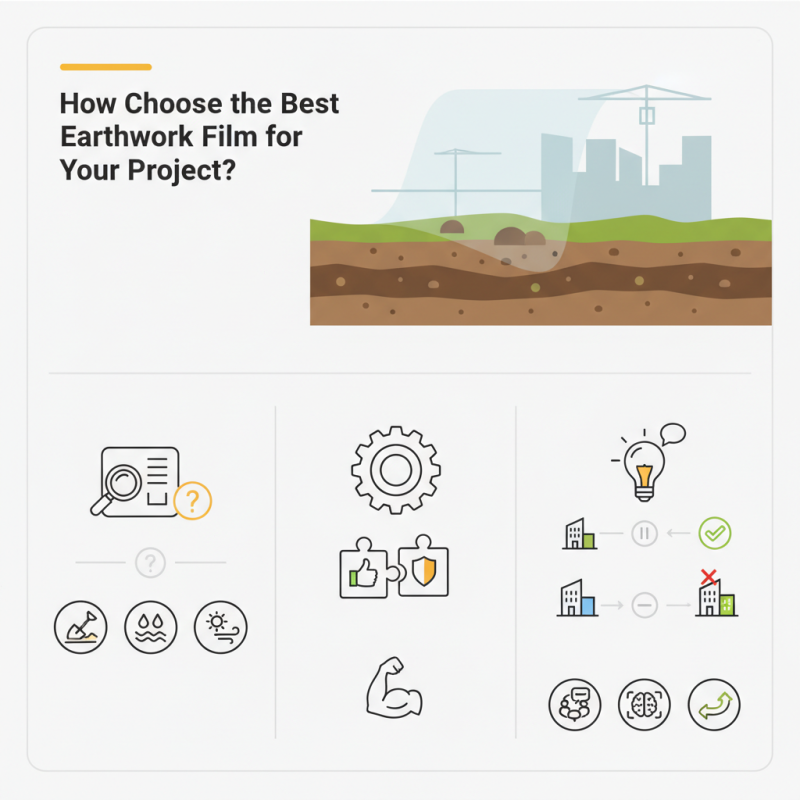

Choosing the right Earthwork Film is crucial for project success. Many factors come into play. You may feel overwhelmed by choices available on the market. Different projects require different types of films.

When selecting an Earthwork Film, consider the specific needs of your site. Factors like soil type, moisture levels, and environmental conditions matter. You want a film that can withstand the rigors of construction. Durability is key. Additionally, compatibility with soil types is essential for long-term performance.

It's not always straightforward. Some films may seem appealing but fall short in actual use. The wrong choice can lead to costly delays or even project failure. It's worth considering the experiences of others. Reflect on past projects and what worked or didn’t. Making informed decisions can lead to a smoother process.

Choosing the right earthwork film can be challenging. Various types of films are available, each with specific applications. Understanding these options is crucial for project success. Two key types are geotextiles and geomembranes.

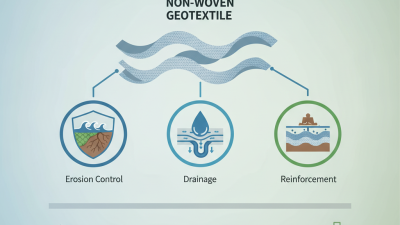

Geotextiles are typically used for soil stabilization. They help separate layers and prevent erosion. According to a report by the Geosynthetics Materials Association, the global geotextile market is expected to reach $7.27 billion by 2026. This indicates a growing demand for effective soil management solutions. Geomembranes, on the other hand, serve as liners. They are essential for containment applications. Their primary function is to prevent leakage and contamination. Research indicates that the continuous use of geomembranes in landfills is critical in reducing environmental risks.

Material choice can also be impacted by budget constraints. Some films may appear cheaper but may lack durability. A less durable film can lead to costly repairs later on. Therefore, while initial costs matter, long-term performance should be considered. Remember, not all projects require the highest grade film. Sometimes, a balance between cost and functionality is needed.

| Type of Earthwork Film | Material | Thickness (mm) | Best Use Case | Average Cost ($ per sq. meter) |

|---|---|---|---|---|

| Geotextile Film | Polypropylene | 0.6 | Soil Stabilization | 1.25 |

| Reinforced Film | HDPE | 1.0 | Erosion Control | 1.80 |

| Woven Geotextile | Polyester | 0.5 | Filtration | 1.00 |

| Non-Woven Geotextile | Polypropylene | 0.8 | Drainage Control | 1.50 |

| Composite Geomembrane | PVC | 1.2 | Containment | 2.50 |

Selecting the right earthwork film for your project requires careful consideration. Key factors come into play, such as soil type, environmental conditions, and project scope. Research suggests that improper film choice can lead to a 30% increase in project costs. The wrong film may not perform well under your project’s specific conditions.

Soil types differ significantly. Organic soils often need films with high permeability. In contrast, cohesive soils may require stronger, more durable options. According to a recent industry report, the failure rate of projects due to incorrect film usage reaches alarming levels, affecting 25% of all earthwork projects.

Environmental conditions matter too. Films must withstand local weather patterns, like heavy rainfall or extreme temperatures. Studies indicate that films designed for specific climates can enhance the overall durability by up to 40%. However, many projects overlook these factors, leading to unexpected challenges and budget overruns. Remember, understanding your project specifics is crucial in making a well-informed choice.

When choosing earthwork films, durability and performance are crucial. A strong film should withstand harsh conditions. It often faces stress from environmental factors. Consider temperature fluctuations, moisture, and UV exposure. Poorly rated films may fail under these pressures. So, always ask for test results and certifications. That information is vital.

Next, evaluate how a film performs under load. Some films excel in lightweight conditions but falter under heavy stress. Remember, not every project has the same requirements. If your site has uneven terrain, look for films that exhibit flexibility and resilience. A rigid film might crack or tear. Think about potential long-term implications too; a flimsy film today could lead to expensive repairs tomorrow.

Finding the right balance is tricky. Sometimes, affordability compromises quality. Opting for the cheapest option might lead to premature failure. It is essential to weigh both short-term costs and long-term gains. Test samples whenever possible. Real-world performance often differs from theoretical expectations. Don’t shy away from seeking feedback from others in the field. Their experiences can illuminate potential pitfalls you hadn’t considered.

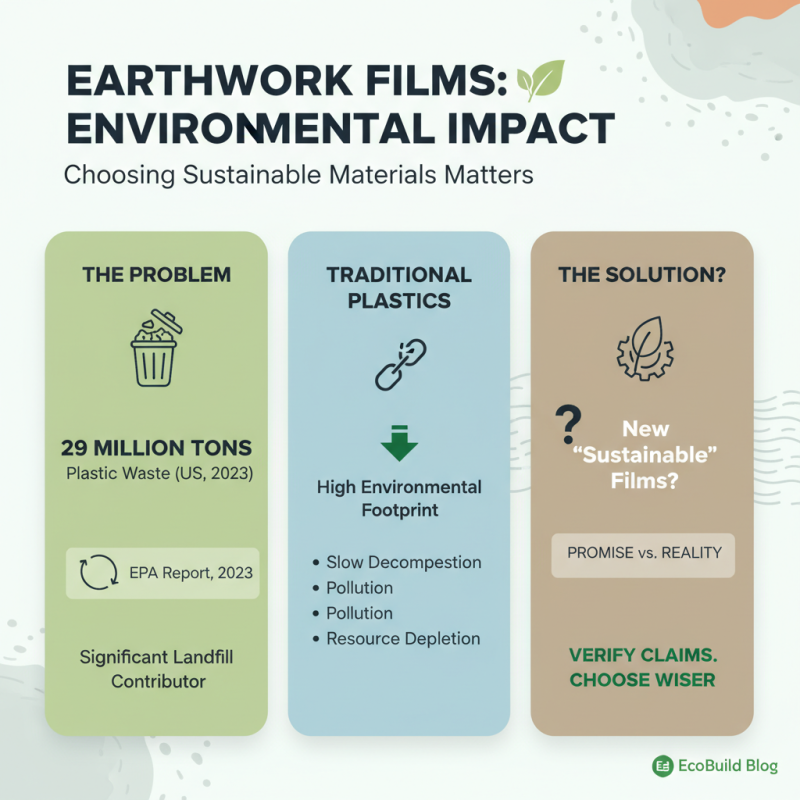

When selecting earthwork films, the environmental impact is crucial. Many new materials claim to be sustainable, but do they truly deliver? According to a 2023 report by the Environmental Protection Agency, common plastic films contribute significantly to landfill waste. In fact, about 29 million tons of plastic waste were generated in the United States alone.

The production of earthwork films often involves harmful chemicals. These chemicals can leach into the soil, affecting local ecosystems. A study by the National Resources Defense Council highlights that certain earthwork films can take over 500 years to decompose. This presents a severe challenge for sustainability in construction.

Evaluating the lifecycle of earthwork films is essential. Consideration must be given to the sourcing of materials and potential recyclability. Simple alternatives, like biodegradable films, may be less durable. Yet they offer a promising way forward. Data suggests that if the construction industry embraces these alternatives, we could reduce plastic waste by up to 30% yearly. Choosing the right film involves balancing durability and environmental responsibility.

Budgeting for earthwork film selection is crucial. First, identify the scope of your project. Is it small or large? This impacts your budget significantly. Earthwork films come with various price points. Understanding your project requirements will help narrow your choices.

Consider the quality of materials. Lower-cost options may seem appealing but might lack durability.

Next, calculate the overall costs. Don’t forget installation and maintenance expenses. Sometimes, cheap options lead to costly repairs. This is a vital aspect that many overlook. Evaluate all potential costs before making a decision.

You may also need to reassess your priorities. A higher upfront cost might offer better long-term value. Quality products reduce the risk of failures. Cheaper materials can lead to poor performance, especially in critical projects. Choosing wisely now can save money in the long run. Take the time to analyze your choices carefully. Consider both immediate needs and future implications.