In the ever-evolving landscape of construction and drainage solutions, the choice of materials plays a crucial role in project success. One material that has gained significant traction in recent years is the Plastic Drainage Pipe. According to Dr. Emily Carter, a renowned expert in civil engineering and drainage systems, “The versatility and durability of Plastic Drainage Pipes make them an ideal solution for a wide range of projects, from residential landscaping to large-scale infrastructure.”

Plastic Drainage Pipes not only offer excellent resistance to corrosion and chemicals but also come in lightweight options that simplify handling and installation. This makes them an attractive alternative to traditional materials like concrete or metal pipes. As environmental considerations become increasingly important in construction, the long-lasting performance and recyclability of plastic make these pipes even more appealing.

Ultimately, choosing the right drainage system can significantly impact the efficiency and longevity of water management in any project. With insights from industry experts like Dr. Carter, it's clear that Plastic Drainage Pipes deserve serious consideration for anyone looking to enhance their drainage solutions.

Plastic drainage pipes have become increasingly popular in civil engineering applications due to their numerous benefits over traditional materials. One of the primary advantages is their lightweight nature, which simplifies transportation and installation. This characteristic not only reduces labor costs but also allows for quicker project completion. Furthermore, the flexibility of plastic pipes enables them to adapt to various site conditions without compromising structural integrity.

Another key benefit of plastic drainage pipes is their resistance to corrosion and chemical degradation. Unlike metal or concrete alternatives, plastic pipes remain unaffected by the harsh environmental conditions commonly found in drainage systems. This durability ensures a longer service life, minimizing maintenance needs and costs over time. Additionally, plastic drainage pipes offer smooth interior surfaces that enhance flow efficiency, reducing the risk of clogs and backups in drainage systems. These qualities make plastic an ideal choice for civil engineering projects that require reliable and long-lasting drainage solutions.

When considering materials for drainage systems, the durability and longevity of plastic pipes stand out against traditional options like metal or clay. Plastic drainage pipes, made primarily from materials such as PVC or HDPE, are resistant to corrosion, which significantly extends their lifespan. Unlike metal pipes that can succumb to rust and abrasiveness over time, plastic pipes maintain their integrity under various environmental conditions. This resistance helps prevent leaks and reduces the need for frequent replacements, making them a cost-effective solution in the long run.

Furthermore, plastic pipes are designed to withstand extreme weather conditions and soil movements, making them ideal for diverse landscapes. Their lightweight nature allows for easier handling and installation, reducing labor costs while minimizing the risk of damage during transport and placement. As these pipes can endure high levels of pressure and stress without cracking, they are exceptionally reliable for both residential and commercial projects. The combination of strength and flexibility found in plastic drainage pipes ensures that they will remain functional and effective for many years, proving to be a wise investment for any drainage system project.

The installation of plastic drainage pipes presents a compelling case for cost-effectiveness in construction projects. According to a report by the American Society of Civil Engineers (ASCE), the initial installation costs of plastic drainage systems, specifically High-Density Polyethylene (HDPE) and PVC, can be 30% to 50% lower than traditional materials such as concrete. This significant reduction in upfront expenses is primarily attributed to the lightweight nature of plastic pipes that require fewer labor hours and less specialized equipment for installation.

Further analysis indicates that the long-term financial benefits of using plastic drainage pipes extend beyond initial savings. A study published in the Journal of Infrastructure Systems highlights that plastic drainage systems are less prone to corrosion and degradation, resulting in a lifecycle that is 2 to 3 times longer than that of traditional materials. This durability translates to lower maintenance costs and reduced frequency of replacements over decades, offering project managers and property owners substantial savings over time. Additionally, the environmental benefits associated with the recyclability of plastic materials align with growing sustainability initiatives in construction, further enhancing their economic appeal.

| Parameter | Plastic Drainage Pipe | Traditional Pipe | Savings (%) |

|---|---|---|---|

| Initial Cost per Meter | $1.50 | $3.00 | 50% |

| Installation Cost | $0.75 | $1.50 | 50% |

| Lifespan (Years) | 50 | 30 | N/A |

| Maintenance Cost per Year | $50 | $100 | 50% |

| Total Cost over Lifespan | $3,000 | $6,000 | 50% |

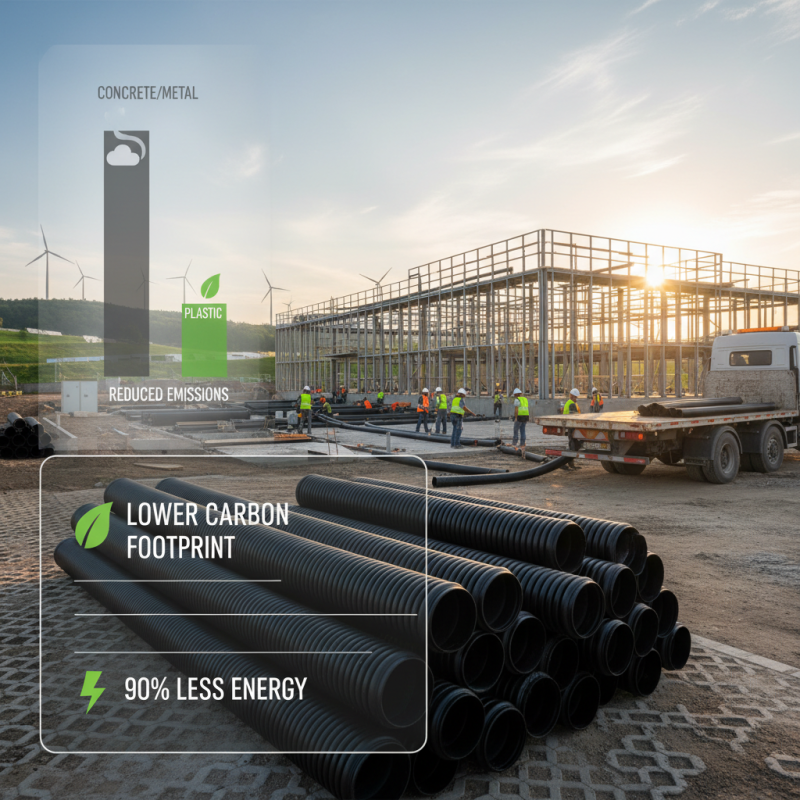

The environmental impact of construction materials is an increasingly critical consideration in today’s sustainable building practices. When it comes to drainage systems, plastic drainage pipes stand out due to their lower carbon footprint compared to traditional materials like concrete and metal. According to a study by the Plastic Pipe Institute, the production of plastic pipes requires up to 90% less energy than metal alternatives. This significant reduction in energy consumption translates into fewer greenhouse gas emissions, making plastic a preferable choice for environmentally-conscious projects.

Furthermore, plastic drainage systems are highly durable and resistant to corrosion, which means they have a longer lifespan and require less frequent replacement. A report from the Environmental Protection Agency suggests that the use of such materials can lead to reduced waste in landfills, further promoting sustainability in construction. Moreover, the recyclability of plastic not only contributes to a circular economy but also minimizes the raw material consumption for future projects.

Tips:

1. When selecting drainage materials, consider the lifecycle analysis of products to understand their environmental impact thoroughly.

2. Always choose products with recycled content to enhance sustainability efforts and support the circular economy model.

3. Collaborate with suppliers who prioritize eco-friendly practices and can provide data on the environmental benefits of their products.

When considering the implementation of plastic drainage pipes in construction projects, understanding the governing industry standards and regulations is crucial. The American Society for Testing and Materials (ASTM) sets forth stringent criteria for the manufacturing and performance of plastic pipes, ensuring they meet safety and durability benchmarks. For example, ASTM D3034 outlines the specifications for PVC pipes used in gravity sewer applications, emphasizing criteria such as impact resistance and stiffness. According to a 2022 report from the Plastic Pipe Institute, adherence to these standards not only enhances the reliability of installations but also fosters compliance with federal and state regulations regarding waste management and environmental protection.

Furthermore, the National Association of Home Builders (NAHB) underscores that plastic drainage pipes contribute to sustainable building practices through their recyclability and reduced carbon footprint. A study by the Green Building Council reveals that plastic pipes can lead to a 70% reduction in greenhouse gas emissions compared to traditional materials during manufacturing and installation. Regulations from the Environmental Protection Agency (EPA) also specify minimum performance expectations for drainage systems to prevent contamination and promote efficient drainage solutions. By adhering to these industry standards and regulations, project managers can ensure that their choice of plastic drainage pipes supports both environmental stewardship and regulatory compliance.