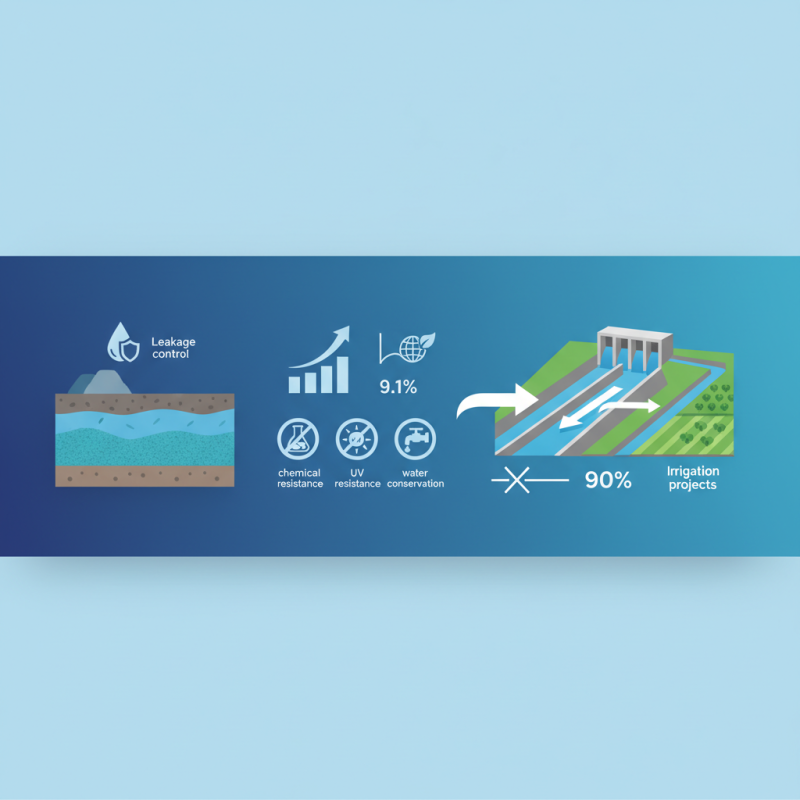

In the realm of modern water management solutions, the choice of materials plays a pivotal role in ensuring sustainability and efficiency. The utilization of PE geomembrane has gained considerable traction among engineers and environmental specialists alike, primarily due to its outstanding properties. According to the Geosynthetic Institute's latest report, the market for geomembranes is expected to grow at a CAGR of 9.1% from 2021 to 2026, underscoring the increasing reliance on products like PE geomembrane for applications ranging from landfill liners to irrigation projects.

PE geomembranes are renowned for their high resistance to chemical exposure and UV radiation, providing long-lasting performance in various environmental conditions. A study published by the Environmental Protection Agency highlights that over 90% of geomembrane failures can be attributed to inadequate material selection or installation, emphasizing the importance of choosing the right product for water management projects. The reliability and durability of PE geomembrane not only ensures effective leakage control but also optimizes water conservation efforts, aligning with global initiatives aimed at sustainable resource management. As the industry progresses towards innovative water solutions, PE geomembrane stands out as a critical component in achieving both environmental protection and economic efficiency.

Water management is an integral part of modern infrastructure, as it directly impacts sustainability and public health. According to a 2022 report by the World Bank, inefficient water management causes global economic losses amounting to over $500 billion annually. Effective strategies in water management are essential, especially in urban areas where growing populations place significant strain on existing resources. Incorporating advanced materials like geomembranes can enhance water retention, mitigate leakage, and improve overall efficiency in managing precious water supplies.

When planning a water management project, consider implementing these tips:

The integration of innovative materials, such as pe geomembranes, not only ensures the integrity of water containment systems but also supports the broader goal of sustainable infrastructure. Research from the U.S. Environmental Protection Agency emphasizes that utilizing proper materials can reduce contaminant migration and support the longevity of water management systems. As we move toward future development, embracing effective water management practices will be crucial to meeting both environmental and societal needs.

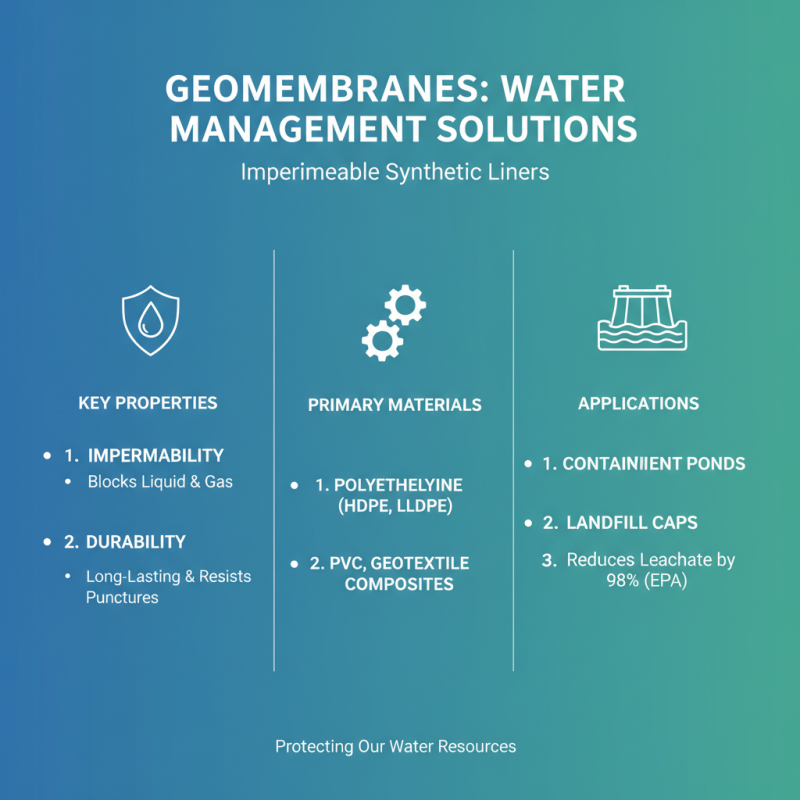

Geomembranes are synthetic membranes used widely in various water management applications, primarily for their impermeability and durability. Made from materials such as polyethylene, these geomembranes are vital in projects like containment ponds, landfill caps, and water reservoirs. According to a report by the Environmental Protection Agency (EPA), the use of geomembranes can significantly reduce leachate rates in landfills by up to 98%, providing an effective barrier against groundwater contamination.

In the realm of water management, geomembranes offer both environmental protection and economic benefits. For instance, a study conducted by the Geosynthetics Institute indicates that geomembrane liners can lower evaporation losses in water reservoirs by a staggering 95%. This data underscores the importance of geomembranes in areas where water conservation is critical, particularly in arid regions. Furthermore, the flexibility and resilience of geomembranes ensure they can be effectively integrated into various designs, providing a tailored solution for diverse projects while maintaining structural integrity over time.

The adoption of geomembranes not only mitigates environmental risks but also enhances the efficiency of water management systems. As water scarcity becomes an increasingly pressing issue worldwide, the strategic use of geomembranes can play a pivotal role in safeguarding water resources and improving sustainability practices within the industry.

When selecting materials for water management projects, PE geomembranes stand out due to their numerous benefits. One of the primary advantages is their exceptional durability. According to industry reports, PE geomembranes can last over 50 years when properly installed, making them a long-term, cost-effective solution. Their resistance to UV radiation and extreme temperatures ensures they perform well in various environmental conditions, which is crucial for applications like landfills, aquaculture, and water containment systems.

Another significant benefit of PE geomembranes is their impermeability. Data from the Geosynthetic Research Institute suggests that PE geomembranes can achieve less than 1 x 10^-7 cm/s permeability rates, which minimizes the risk of leakage and contamination of groundwater. This feature is essential for protecting water resources and maintaining compliance with environmental regulations. Furthermore, the ease of installation and adaptability of PE geomembranes allow for quick and efficient project completion, reducing labor costs and time.

Tips: When choosing a PE geomembrane, consider the specific requirements of your project, such as thickness and color, which can influence thermal performance and longevity. Additionally, ensure that proper installation practices are followed to maximize the lifespan and effectiveness of the geomembrane in your water management system.

| Benefit | Description | Application Example |

|---|---|---|

| Durability | High resistance to physical stress, UV radiation, and chemical exposure. | Landfill liners and wastewater treatment facilities. |

| Cost-Effectiveness | Lower installation and maintenance costs compared to alternative materials. | Irrigation systems and pond liners. |

| Flexibility | Easily conforms to complex shapes and surfaces. | Water storage tanks and lakes. |

| Environmental Protection | Prevents contamination of soil and groundwater. | Contaminated site remediation and agricultural run-off control. |

| Ease of Installation | Quick and straightforward installation process, reducing labor costs. | Construction of containment barriers. |

When considering materials for water management projects, the choice of geomembrane can significantly impact both performance and cost-efficiency. Polyethylene (PE) geomembrane stands out in comparison to other materials, particularly when it comes to durability, flexibility, and resistance to environmental stressors. According to data from industry reports, PE geomembranes typically demonstrate a tensile strength of over 4000 psi, allowing them to withstand heavy loads and adverse weather conditions better than alternatives such as PVC or EPDM.

In addition to mechanical strength, the chemical resistance of PE geomembrane makes it a preferred choice for various applications, particularly in environments involving hazardous substances. Research indicates that while PVC geomembranes may offer lower upfront costs, their susceptibility to UV degradation and chemical leaching can lead to higher long-term maintenance costs, nearly double that of PE solutions. Furthermore, studies suggest that the longevity of PE geomembrane can surpass 30 years when properly installed, which can be a compelling factor for project managers aiming for sustainability and cost-effectiveness over the lifecycle of a project.

Overall, the comparative analysis indicates that PE geomembranes provide enhanced performance attributes over other materials, making them a superior choice for water management applications. The combination of mechanical reliability, chemical resistance, and longevity contributes to their increasing adoption in the industry, particularly as environmental standards become more stringent.

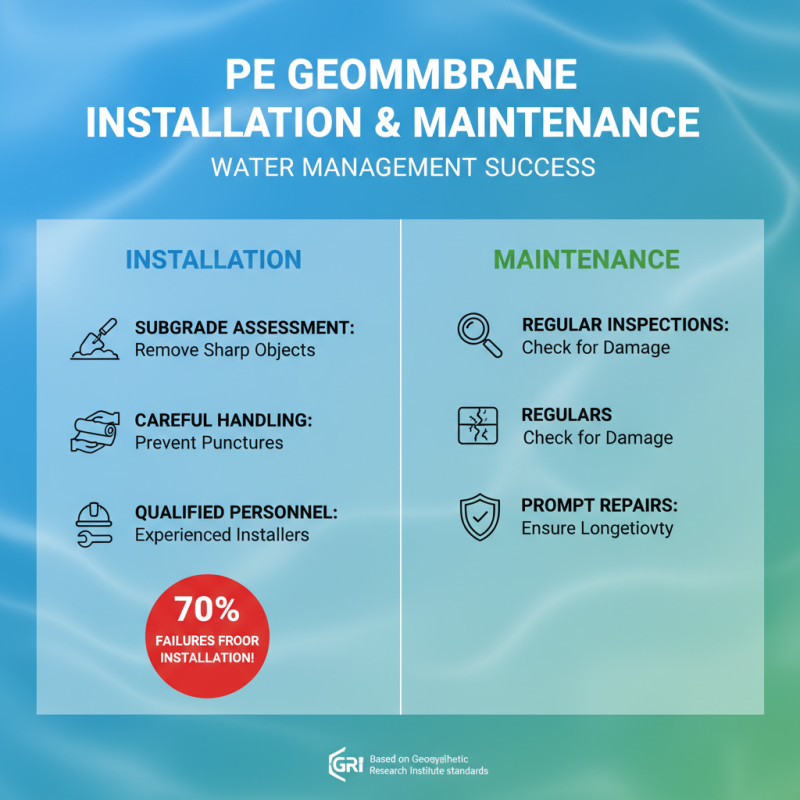

When considering installation and maintenance for PE geomembranes in water management projects, several critical factors come into play to ensure optimal performance and longevity. Proper installation is fundamental; studies have shown that up to 70% of geomembrane failures result from poor installation techniques. For example, it is essential to assess the subgrade conditions thoroughly, as any sharp objects or irregularities can lead to punctures over time. The recommended installation methods include careful handling and placement, as well as utilizing qualified personnel who have experience with geomembrane applications, as outlined in the Geosynthetic Research Institute's reports.

Maintenance is equally crucial to extend the life of PE geomembranes. Regular inspections should be performed to identify any visible damage or signs of wear, such as rips, tears, or UV degradation, which can decrease the material's effectiveness. According to the Federal Highway Administration, routine maintenance checks can improve the lifespan of geomembranes by up to 30%. In addition, adopting protective measures, such as integrating a protective cover or layer, can shield the geomembrane from environmental stressors like intense sun exposure and mechanical abrasion. By implementing these installation and maintenance practices, water management projects can leverage the full benefits of PE geomembranes, enhancing their durability and functionality.